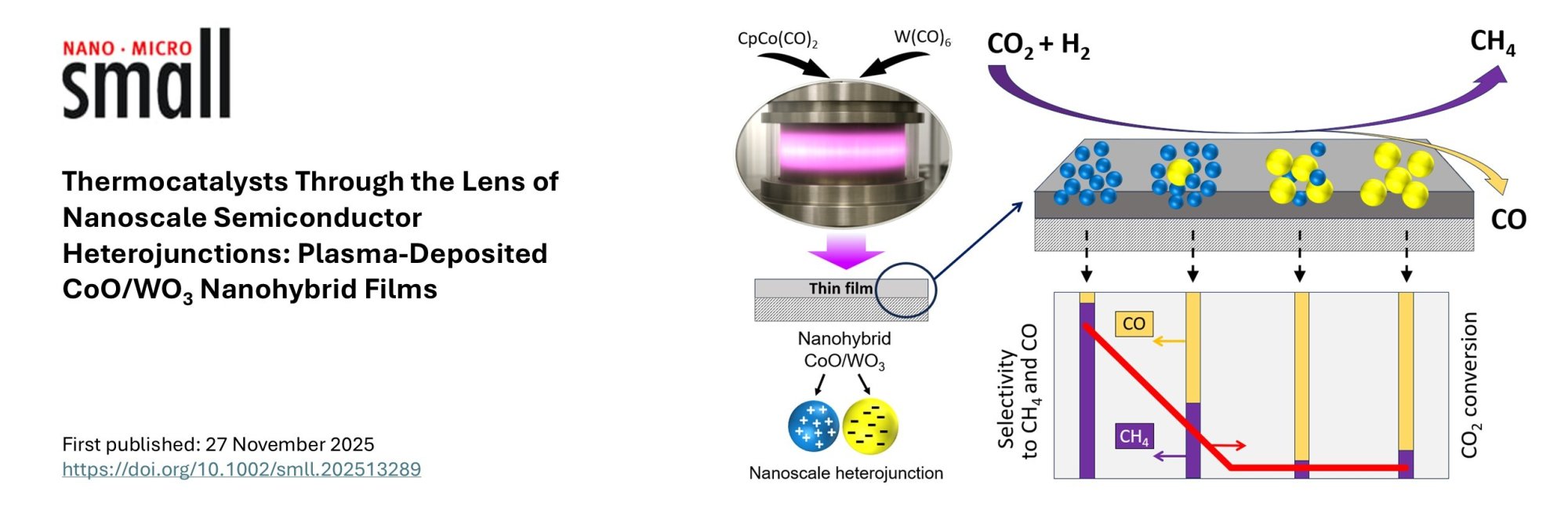

Why CoO behaves differently in the presence of WO3 in CO2 methanation – nanoscale insights from plasma-deposited CoO/WO3 films

Our new research published in Small asks a fundamental question: What truly drives the “synergy” and “anti-synergy” observed in multicomponent nanocatalysts?

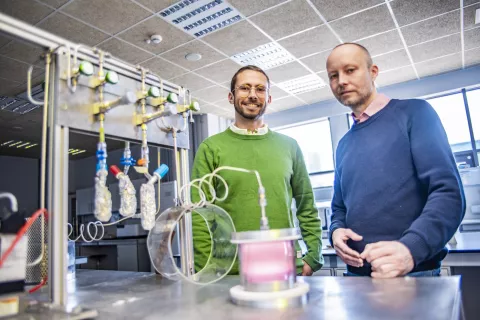

We show that nanoscale charge modulation in plasma-deposited CoO/WO₃ nanohybrids governs catalytic behavior in CO2 methanation. By revealing heterojunctions at the level of individual nanoparticles, the study provides a physical explanation for the drastic change in CoO reactivity. While our “plasma” catalysts containing CoO nanoparticles are typically highly active in methane formation from CO2 and H2, in the CoO/WO3 nanohybrid they acquire positive charge, which—consistent with active-site theory—accounts for the observed shift in performance: CoO completely loses selectivity toward methane.

These insights advance the rational design of nanohybrid catalytic systems.

👉 Read the full article: https://onlinelibrary.wiley.com/doi/10.1002/smll.202513289

2026-02-10

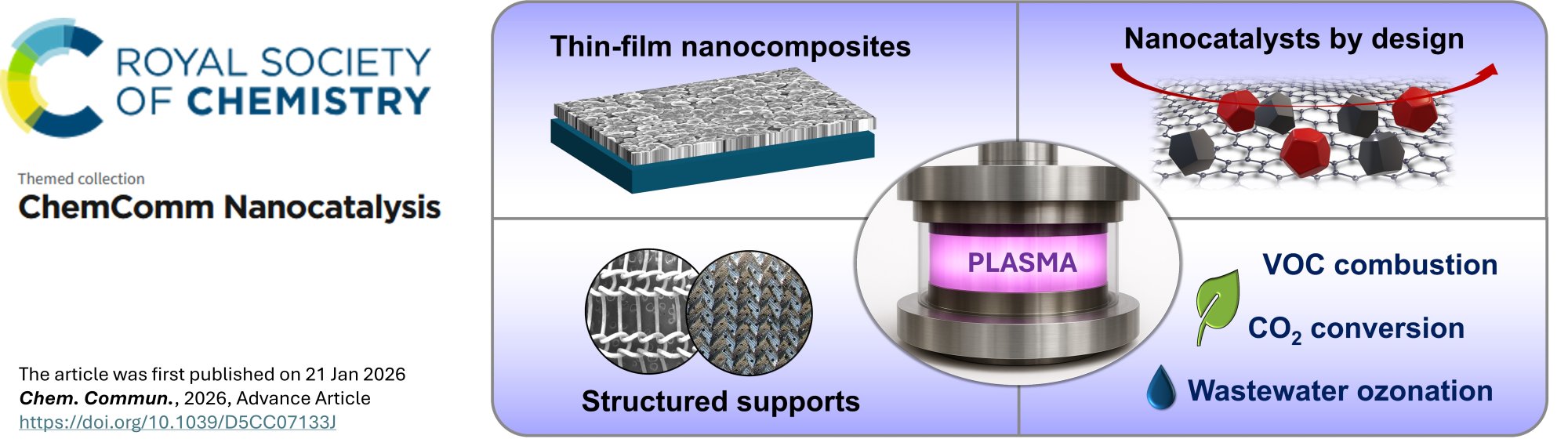

Cold plasma for efficient thin-film catalysts – our latest review just published

We are pleased to announce the publication of our review article “Cold plasma deposited thin film nanocomposites for heterogeneous thermocatalysis – concepts and progress” in Chemical Communications in the themed collection ChemComm Nanocatalysis (Open Access).

The article was prepared upon invitation from the RSC editorial team as an overview of current research directions in the field of plasma-deposited thin-film catalysts. The paper highlights how cold plasma technologies enable the fabrication of advanced thin film nanocomposite catalysts with precisely controlled architecture and electronic structure. When deposited on 3D supports, these films open new pathways for efficient and scalable thermocatalytic processes, such as:

- CO2 conversion

- VOC combustion

- Wastewater ozonation

The article is based on many published results from our team and shows the growing potential of thin film catalysts for a variety of applications. It also indicates a significant influence of heterojunctions on the catalytic activity of the “plasma” nanocomposites.

👉 Read the full article here: https://doi.org/10.1039/D5CC07133J

2026-02-04

Poland–China collaboration: Plasma-prepared catalysts for CCUS technologies

From November 12 to 25, 2025, we hosted Liju Bai from the School of Chemistry and Chemical Engineering, Beijing Institute of Technology (China). The visit was funded under the PROM project (FERS.01.05-IP.08-0218/23) .

Liju Bai is pursuing a Ph.D. entitled “Design and Process Research for High-Performance Carbon Capture Materials” under the supervision of Prof. Helei Liu . Research in this area, conducted at the Department of Molecular Engineering under the guidance of Prof. Hanna Kierzkowska-Pawlak, focuses on designing innovative thin-film catalysts for CO₂ capture and conversion. During the internship, under the supervision of Dr. Ryszard Kapica, Liju Bai fabricated nanostructured catalysts using the PECVD method, which will be applied to intensify CO₂ capture processes. The efficiency of these catalysts and their impact on the performance of CO₂ removal processes will be tested in laboratory-scale CO₂ capture installations in China.

2025-11-26

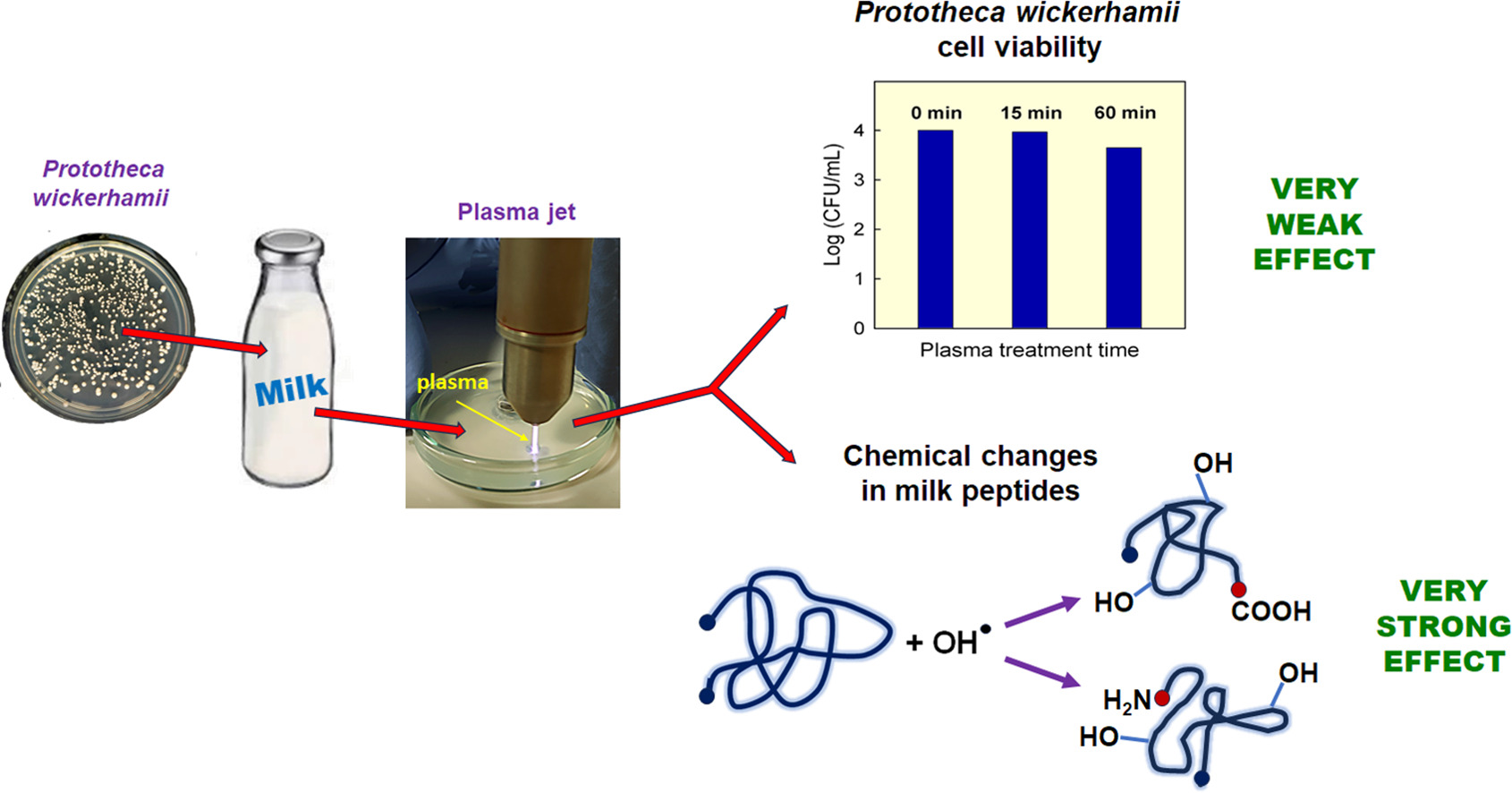

Revealing the limits of cold plasma in dairy decontamination

Top-ranked Food Chemistry publishes our research on plasma inactivation limits in milk

Our team from the Division of Molecular Engineering ( prof. J. Tyczkowski and dr R. Kapica), in collaboration with the Medical University of Lodz and the Centre of Molecular and Macromolecular Studies (Polish Academy of Sciences), has published a new study in Food Chemistry (Vol. 480, 2025). The research reveals that protein fractions in cow milk significantly reduce the effectiveness of cold atmospheric plasma in inactivating Prototheca algae by scavenging OH radicals. These results highlight important limitations for plasma-based decontamination in dairy processing and have broader implications for plasma applications in food and medicine.

2025-05-19

Advancing nanoparticle functionalization: PROM research stay of Gabriel Marques

Gabriel Marques, a second-year PhD student in Physics Engineering from the University of Aveiro, is spending three weeks (24.02.2025–15.03.2025) at the Division of Molecular Engineering at Lodz University of Technology as part of the PROM program.

Gabriel's research focuses on the functionalization of silica nanoparticles with organic dyes and their optical characterization. His objective is to optimize the functionalization process to achieve controllable optical properties, which can be applied in sensors for leak detection. During his stay, under the supervision of Dr. Jacek Balcerzak, he is utilizing X-ray Photoelectron Spectroscopy (XPS) to gain crucial insights into the surface chemical structure of nanoparticles and to correlate these findings with their optical properties.

Autor: Marcin Szmidt

Our team proposes a novel approach to the “alchemy” of catalysts

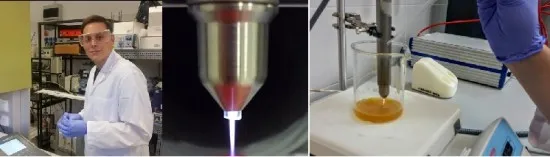

What's the deal with synergy? The role of heterojunctions in nanohybrid catalysts for thermal catalysis

Solid catalysts, often nanoscale materials, are at the heart of many technologies. In the recent Perspective „Classical Concept of Semiconductor Heterojunctions in the Approach to Nanohybrid Catalysts” (J. Tyczkowski & H. Kierzkowska-Pawlak) we explored the secrets of nanohybrid catalysts—nanocatalysts composed of two different materials with distinct electronic structures. We identified key interactions that influence the reactivity of such multicomponent nanocatalysts, often described as "synergy". Our findings show that the formation of heterojunctions—regions filled with electric charges—between these materials can span the entire volume of the interacting components (nanoparticles), significantly affecting their catalytic properties. This charge effect plays a crucial role in governing catalytic activity in thermal catalysis. By understanding interactions between different materials and the resulting charge flow, we can take a rational approach to designing novel, more effective catalysts for numerous industrial processes, such as CO₂ hydrogenation, catalytic converters in vehicles, biomass conversion, and many others. The new finding is reported in the journal ACS Applied Materials & Interfaces and was featured on the cover. Although still in its early stages, this concept could have a profound impact on developing more effective nanohybrid catalysts tailored to specific needs.

What's more, we proposed a highly promising and proven method for fabricating nanohybrid catalysts: cold plasma deposition. We demonstrated how a cold plasma technique can be used to design and control both the molecular structure and nanostructure of nanohybrids with heterojunctions. The provided proof-of-concept examples highlight the significance of interface interactions in nanohybrid materials in charge flow manipulation and utilization for enhancing catalytic activity and improving reaction selectivity in CO₂ hydrogenation processes.

More about this research on the TUL blog, the ACS Publications blog, and in Życie Uczelni (in Polish).

About the Cover: The formation of a heterojunction between nanoparticles of two different semiconductors, according to the classical concept, induces space charges within their volume. This can drastically improve the catalytic activity of such nanohybrids in thermocatalytic processes compared to the isolated nanoparticles.

11.09.2024

Cold plasma modification of magnesium powders for biomedical applications

Between October 10th and November 8th, 2022, our Department hosted a Ph.D. student from the Institute of Materials and Machine Mechanics, Slovak Academy of Sciences (link) — Veronika Nagy Trembošová (ResearchGate). The internship was financed by the PROM Program (link). During her stay, we worked on developing a facile method to modify the surface of Mg/MgO powders to improve anti-corrosion properties using cold plasma. The powders were treated under varied conditions, forming a protective layer of magnesium carbonate on the surface. The obtained results open promising possibilities for further use of the plasma-modified powders as Mg-based bioimplants.

2022-11-12

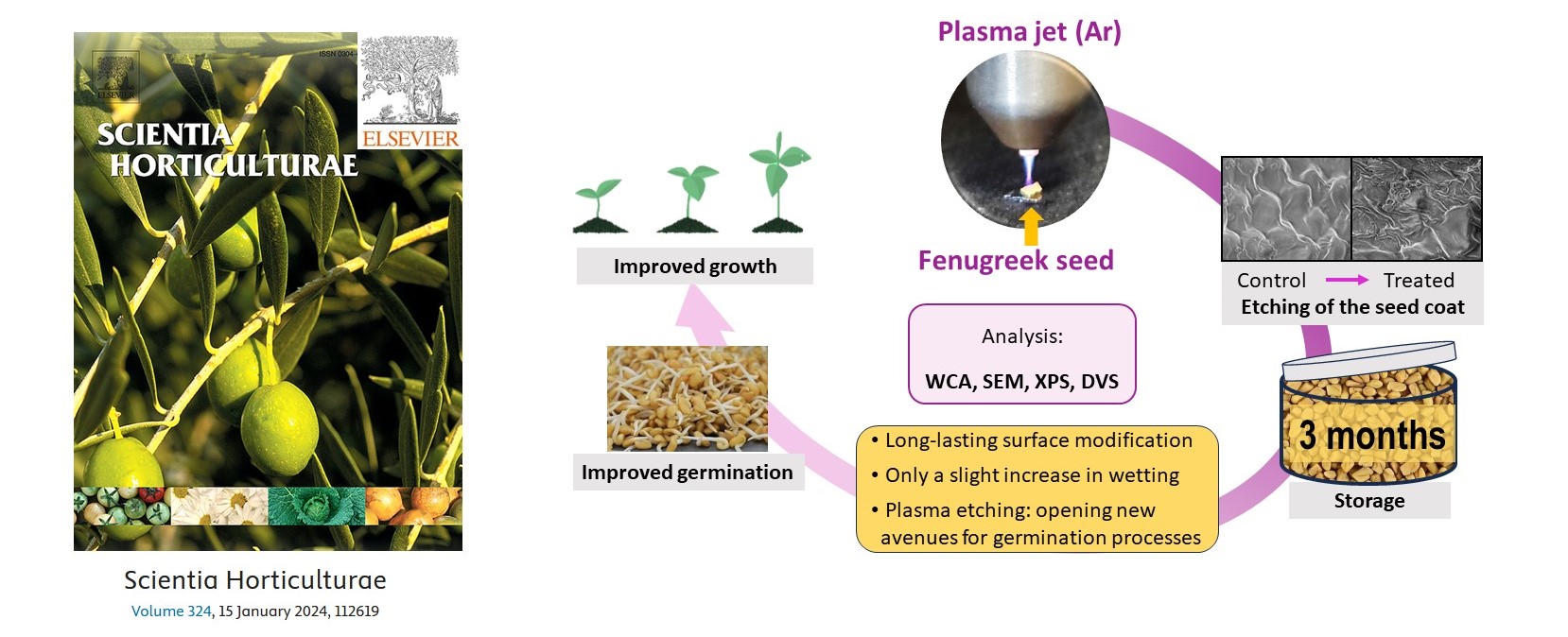

Collaborative research reveals long-lasting effects of cold plasma on seeds

A recent article published in Scientia Horticulturae presents important findings from a research collaboration between our Department and Kathmandu University (Nepal). The study “Germination improvement of fenugreek seeds with cold plasma: Exploring long-lasting effects of surface modification”, uncovers that cold plasma treatment induces stable, long-term structural changes in the seed coat that remain effective even after several months of storage.

We demonstrated that short exposures to cold plasma significantly enhanced germination efficiency and seedling vigor three months after treatment, proving that plasma-induced modifications are not temporary but persist over time. Microscopic and chemical analyses confirmed etching and restructuring of the seed surface, which likely facilitates improved metabolic activity during germination. This plasma-based scarification positions cold plasma technology as a powerful tool for long-term enhancement of seed germination in agriculture.

👉 Read the full article here: https://doi.org/10.1016/j.scienta.2023.112619

2023-11-02

Cold plasma for innovative agriculture: effect of cold plasma treatment on seed germination and seedling development

Recently, we hosted a Ph.D. student from Kathmandu University — Rajesh Prakash Guragain (Deepak Prasad Subedi's Lab). Rajesh participated in a short research internship (03–30.03.2022) aimed at measurements using unique equipment available at the Department of Molecular Engineering (PROM programme-NAWA). He worked on surface modification of various seeds (radish, carrot, soybean, wheat, etc.) via cold plasma treatment to enhance germination. The research focused on understanding mechanisms of plasma-seed treatments. Cold plasma technology shows great potential in seed processing for agricultural purposes!

2022-03-30

Electrical properties of cold plasma-produced thin nanohybrid layers based on the carbon family

Together with M.Sc. Kaya Chakmak, our guest from the ERASMUS program (Akdeniz University, Turkey), we investigated the conductivity of cold plasma-produced Sn-C and Co-C thin nanohybrid films. Based on macro-scale current-voltage characteristics and nano-scale measurements using conductive atomic force microscopy (CAFM), we obtained results relevant for potential application of the layers for water splitting into hydrogen and oxygen.

2021-08-05

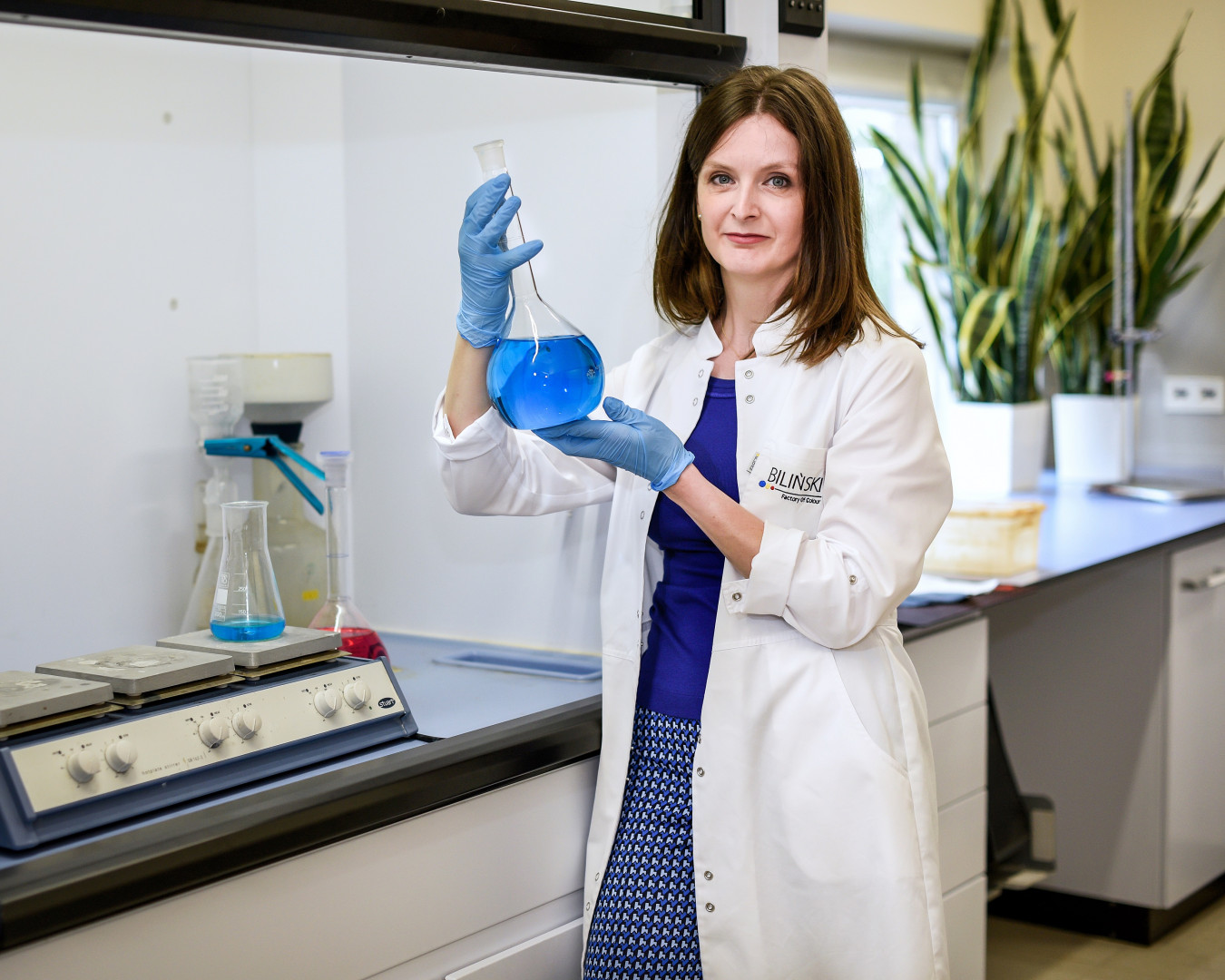

Plasma in the fight against textile sewage

To present the aim of the project "Modern technology for the treatment and recycling of textile sewage implemented using plasma catalysts", the following questions should be answered: why does it concern the textile industry? and how can cold plasma help achieve sustainable development goals?

The textile industry is deeply rooted in the history of Łódź, and the ubiquitous post-industrial architecture does not allow us to forget about textiles as the driving force that created and shaped this city. The anthem of Łódź is the song "Prząśniczka". The textile industry still strongly defines the economic structure of the region. According to the Association of Employers of the Clothing and Textile Industry (PIOT) statistics, over 100,000 people are employed in this industry in the Łódź region.

The project plans to use innovative cold plasma techniques to produce thin-layer catalysts deposited on a solid substrate with complex geometry. This will create modern, active nanostructured materials covering the surface of the metal mesh. These materials will act as heterogeneous catalysts in the ozonation process, increasing pollutant removal efficiency. The project will be implemented with participation of Prof. Jacek Tyczkowski's research team, who have many years of experience in cold plasma techniques. The developed technical solution (reactor with plasma catalyst) will be tested on a larger scale in industrial conditions.

2021-06-10

Novel plasma-deposited photocatalysts for photoelectrochemical water-splitting

The partnership agreement between the Lodz University of Technology and the Research Institute of Electronics (RIE) of Shizuoka University (Japan) resulted in a recent visit of PhD student Vytautas Kavaliunas from RIE Shizuoka University. MSc Kavaliunas participated in short-term education aimed at taking measurements with unique equipment of the Department of Molecular Engineering and obtaining materials for a Ph.D. thesis.

During his stay, Vytautas Kavaliunas and team established a method of TiO2 thin-film preparation via cold plasma deposition (PECVD), as the top layer of a novel multi-layer anode for the photoelectrochemical water-splitting process. Electrochemical water decomposition with solar irradiation is one of the most promising ways for green hydrogen production, but efficient photoactive catalyst development is required.

Novel photocatalysts were studied using XPS, UPS, and UV-Vis spectroscopy. Photocatalytic properties of the anodes were examined via electrochemical LSV analysis of the oxygen evolution reaction (OER) in basic electrolyte solution. The study of water splitting with the obtained anodes will continue in both the Department of Molecular Engineering and RIE Shizuoka University.

2021-04-10

Recent advances in cold plasma applications in water splitting and CO2 conversion

The new applications of cold plasma were investigated in our department within the following master projects (TUL-TU Dortmund University):

Conversion of CO2 in a cold plasma reactor – Arne Schemann (TU Dortmund University)

Water splitting to hydrogen over novel plasma-deposited photocatalysts – Sheikh 'Ahmed' Mujaddadi (TU Dortmund University)

2020-01-20

Thin layers deposited by cold plasma for electrochemical applications – collaboration with Jagiellonian University and AGH University of Science and Technology

Another research topic was initiated during the stay of Maria Madej (PhD student, Jagiellonian University, Faculty of Chemistry, Department of Analytical Chemistry, Supervisors: Prof. Jolanta Kochana, Prof. Bogusław Baś) and Justyna Lipińska (PhD student, AGH University of Science and Technology, Faculty of Materials Science and Ceramics, Faculty of Analytical Chemistry, Supervisor: Prof. Bogusław Baś). Preliminary tests were conducted on new layers applied using cold plasma for electrochemical sensors. Research focuses on optimizing layering parameters to achieve best electrical conductivity while maintaining high mechanical strength of layers.

2019-07-31

Cold plasma for a rational modification of MOFs – collaboration with Universidad Rey Juan Carlos (Madrid)

A new research topic was started during the stay of Jesus Tapiador Cebrian, Ph.D. student from Universidad Rey Juan Carlos, Chemical and Environmental Engineering Group, supervised by Prof. Guillermo Calleja and Dr Gisela Orcajo. Cold plasma treatment was applied for rational modification of MOFs developed by the Spanish group. MOFs (metal-organic frameworks) are advanced functional materials with very high porosity and well-defined structure. Our research focuses on optimizing their structural and functional characteristics for improved performance as catalysts (CO2 conversion, dye degradation) and for hydrogen storage applications.

2019-07-23